Save energy

As a brand new benefits your now have the possibility to buy many kinds of hotmelt, who can be melted and used by much lower temperature than today.

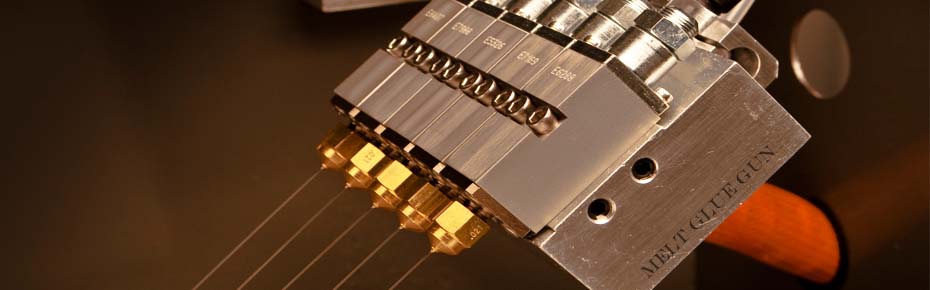

A new series of hotmels for edge bonding can be used only by 150 degrees C, compared to traditional EVA types who must be applied by 200 degrees C. The exact saving depends of the equipment, which is size of vessel, eventual front melt, how many heated hoses and guns, but typically you can save 30-40 % of energy.

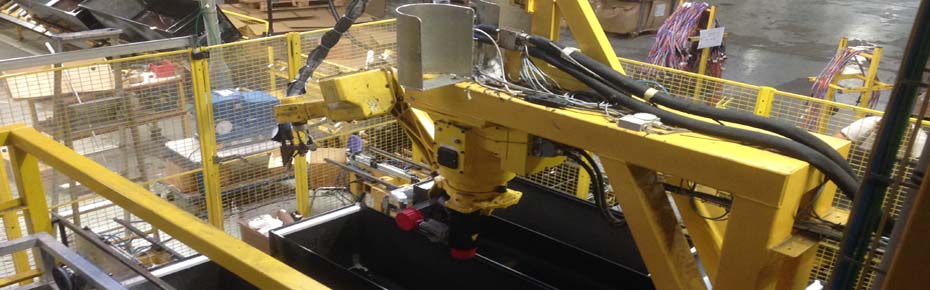

When you close your boxes by using hotmelt can you have the same size of savings. In the range you see a wide range of new APAO types developed to be applied at 120-130 degrees C, compared to EVA types who are applied at 150-170 degrees C.

The soft point (R&B) is the same for all types, or even better in the new types despite the lower applied temperature.

The Danish government has decided that the Danish industry shall decrease the use of energy with 40% before year 2020. In this case we advise precise possibilities how we can help you to reach this target.

Contact GlueLine if you want more information...